Our Quality System...

Wacom Quartz Corporation was set up from it's beginning to operate with an ISO 9000 based managment system.

Our Quality Policy and Mission Statement

Wacom Quartz will develop and improve long lasting partnerships with customers, employees and suppliers that will ensure both customer satisfaction; and a strong, profitable business for a healthy future. The management of Wacom Quartz is committed to continually supporting our stated quality objectives. Thru planning, review, and taking actions to meet those objectives, we support our quality system at all levels of the company.

Certification

Certification

We first applied for and were granted ISO registration in January 2001 (ISO 9002:94); later upgraded that certificate to ISO 9001:2000, and most recently our current ISO 9001:2015. The quality system is monitored by our third party registrar "Amtivo" as well as by regular internal audits and also audits/inspections by our customers upon request.

Five "management level" employees and two others trained as ISO-9001:2015 internal auditors make up the Wacom Quartz Management Review Team. It is this team that is responsible for maintaining our quality system and reports directly to the president of the company. To assist them in doing so we utilize the following systems throughout the organization.

Documentation System

Following the ISO 9000:2015 guidelines, we utilize the following "pyramid" structure for document control; where each lower layer contains more specific information, and "supports" the layers above:

Process Control

The bulk of the ISO 9001:2015 standard is about process control. We have implemented this at Wacom Quartz by developing and using the following tools throughout the organization to control our processes via the PDCA (plan, do, check, act) model:

| ERP Database | Since the third quarter of 2007, we have been using an Enterprise Resource Planning database designed by Epicor® software to control all aspects of our business processes including quoting, sales, purchasing, shop floor control, inspection, shipping and accounting. Some features that allow it to work well as part of our quality system for process control include:

|

| SOP-PC01 | "Process Control" is our largest/longest standard operating procedure and in turn has more specific work instruction documents linked beneath it than any other SOP. Included among these are several "special processes" as defined by ISO-9001 where the direct results of the process are not easily measured, and only by a combination of operator training and experience, input parameter controls, and future follow up will you be able to verify the output of the special process. Some other key areas covered by this document are things such as "General Fabrication" wherein controls for handling and otherwise keeping the product clean are spelled out along with safety concerns; "First Piece Inspection" a key aspect for some of our jobs, and not applicable on others is clearly defined with rules for when to carry it out; and "Rework vs. Nonconforming Decision Making" that has rules for determining when to declare both, and what to do in each case. |

| Shop Flow | The floorplan of Wacom Quartz's main plant was designed from its origin in 1995 to provide a good work flow for fabrication of semiconductor quartzware. This has worked well with our 5S program (see below) and helps prevent mistakes by making the most efficient process steps easier to plan and do. |

| Fabricator In Charge | Working closely with our Training Matrix (which documents who is qualified to do what process) and tied into our ERP system discussed above is our production control method we call "the fabricator in charge." Essential steps for material, paperwork, computer data and conformity status updates are assigned to a specific person at pre-defined key points during each production job. That person then becomes responsible for the control and reporting of those steps. This simple yet effective system controls material and data loss on our shop floor and defines the feed back loop for process improvement projects. |

6S Method

6S Method

Wacom Quartz is on a path toward Lean Manufacturing with our implementation of the "6S" method of process optimization. We have an in-house team of 3 employees that received training from one of our customers and are currently moving through the company bringing the 6S methodology and changes to one department or area at a time.

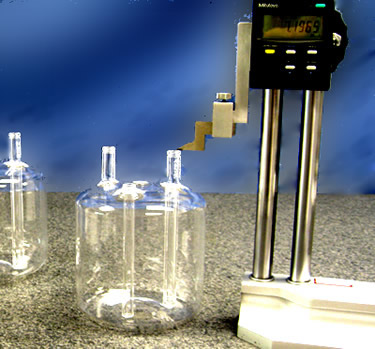

Inspection

Inspection

Unless otherwise specified in a purchase order, every part we make is 100% quality control inspected to meet the dimensions and notes on it's production drawing as well as any written specifications received from the customer. Various electronic and paper records are generated to be shipped with the products or retained for product history.