Glassblowing...

There is evidence of glassblowing taking place as far back as the 24th century BC. Most modern glassblowing is either artistic, labware related, or fully automated for things such as light bulbs.

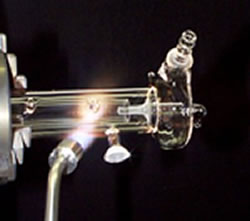

Here at Wacom Quartz we use the term to describe hot-working quartz using glassblowing techniques. (As opposed to welding techniques.) This typically involves spinning a tube or disc on a lathe, rollers, or by hand; then applying heat and or pressure to form a desired shape.

Glassblowing lathes are used to accomplish the same rolling, gathering, stretching and centrifugal force techniques that "traditional" glassblowers use by holding the glass in their hands or rolling a blowpipe across their tables. Heat is applied via custom made hydrogen/oxygen torches, and graphite paddles or other tools are used to shape (or gage the shape of) the hot quartz. Unlike "softer" glass types, pure quartz can only be worked directly in the flame, it hardens nearly instantaniously at room temperature once the direct heat is removed.

Glassblowing lathes are used to accomplish the same rolling, gathering, stretching and centrifugal force techniques that "traditional" glassblowers use by holding the glass in their hands or rolling a blowpipe across their tables. Heat is applied via custom made hydrogen/oxygen torches, and graphite paddles or other tools are used to shape (or gage the shape of) the hot quartz. Unlike "softer" glass types, pure quartz can only be worked directly in the flame, it hardens nearly instantaniously at room temperature once the direct heat is removed.

All but two of the employees of Wacom Quartz are glassblowers or former glassblowers. This nearly forgotten art / skill is the heart of our business. We have litterally hundreds of combined years of experience forming quartz and other types of glass, as of this writing we have on staff 11 master glassblowers with more than 20 years experience.

Wacom Quartz has the talent and equipment to facilitate glassblowing quartzware from the most simple to highly complex. Feel free to challenge us with an order you were told elsewhere "could not be built."